Process Improvement Tools Design Intern Michigan

Leaders who want to develop a culture of rapid continuous improvement have many tools at their disposal. So many, in fact, that it can be difficult to keep them all in mind when deciding how to execute an opportunity for improvement or to address a difficult challenge. Or course, most organizations don't use all of them at any one time, but each can be remarkably effective when applied to the right situation. We put together a list of the most common and useful improvement tools and techniques that you can start implementing today. A3 is a structured problem solving and continuous improvement approach that was first employed at Toyota and typically used by lean manufacturing practitioners. The use of A3s is spreading to organizations in every industry and is pretty common amongst our customers. An A3 report is one page that documents the results from the PDSA cycle. A3s get their name from the A3-sized sheet of paper on which they are designed to fit. The problems with the A3 process typically revolve around transparency, communication, standardization, and long-term institutional knowledge. When you have people all around an organization filling out a complex document on paper, it's nearly impossible to know who is working on what, to get everyone sticking to the standard process, and to share that knowledge with others over time. A3 software like KaiNexus makes it possible to view your A3 electronically in the layout you're used to, with the critical benefits of increasing transparency and accountability. Such software gives you the ability to drill down into the details of any A3 on the spot, and share improvements to drive a more widespread impact. 5S is the name of a workplace organization method that was originally applied in manufacturing, but many organizations in a wide variety of industries have since found that 5S is an effective way to achieve rapid continuous improvement. 5S revolves around five ideas that make people more effective and efficient in their work. It earned its name because each of these five principles starts with the letter "S." Sort: Keep only what is regularly used nearby Straighten: Arrange the space so workers can find exactly what they need to use in less than 30 seconds Shine: Ensure that the workplace and equipment are ready for immediate use Standardize: Each job is done in the same way and everyone is challenged to offer ideas to improve it Sustain: Foster a safe, efficient and effective workplace is everyone's responsibility The idea of catchball is quite simple. Someone starts a rapid improvement or planning project. They define the purpose, goals, background, and challenges, and then "throw" them to other stakeholders for opinions, help, and action. At every point, it is clear who has ownership of the idea (ball). The ball can bounce around back and forth among all of the players until the improvement or plan is complete. What's the point of all this "extra" effort? You hire smart, capable employees for a reason — and it's not just to pull levers or move patients. These people all have the ability to contribute ideas and experience in pursuit of achieving your strategic organizational goals. One of the most effective ways to develop a culture where everyone is working toward the same goals is to connect each layer of the organization, from the c-suite to the front lines, with the corporate strategy. When this alignment is achieved, everyone can work together to deliver value to customers.Catchball is a simple yet powerful tool for rolling out the strategy in such a way that it touches every individual in a meaningful way. DMAIC is a project methodology with five phases; define, measure, analyze, improve, control. These steps are used to help ensure that improvements are data-driven, measurable, and repeatable.The DMAIC improvement cycle is an effective technique for structured change management. The emphasis on measurement and analysis helps ensure that opportunities for improvement are executed in a way that ensures the most positive impact. The Define phase is all about selecting high-impact opportunities for improvementand understanding which metrics will indicate project success. During this phase the leaders will perform activities such as identifying theimprovement opportunity, outline the scope of the project, estimating the project impact, and creating a team. During the Measure phase, existing processes are documented and a baseline is established. Critical activities at this point include (but are not limited to) developing the methodology by which data will be collected to evaluate success, and gathering, plotting, and analyzingcurrent state data. The goal of the Analyze phase is to find and validate the root causes of business problems and ensure that improvement is focused on causes, rather than symptoms. Doing this includes, in part, developing a problem statement, completing a root cause verification analysis, designing measurable improvement experiments, and developing a plan for improvement. Once you reach the Improvement phase, it is time to determine exactly which steps will be taken and begin to roll out the changes that analysis has prescribed. In this stage, it's common to generate and evaluate solution ideas, determine expected solution benefits, and communicate solutions to all stakeholders. The objective of the last stage is to develop the monitoring processes and procedures that will ensure long-term success. To do so, you'll need to do things like verify reduction in failures due to the targeted root cause, determine if additional improvement is necessary to achieve the project goal, update yourStandard Work documentation, and integrate lessons learned. The term "Gemba" means "The real place" in Japanese. The Gemba walk technique involves managers or supervisors going to the place where work gets done to observe and identify opportunities for improvement. Only after the walk is complete and a period of reflection occurs are changes implemented. Here are some do's and don'ts for Gemba Walks. The idea behind Gemba walks is that it's the staff on the front lines of any workplace that have the best ideas for how to improve their work, since they're the ones doing the work. They'll come up with small, low-cost, low-risk improvements that add up to a significant impact - and are ideas that senior leaders never would have thought up in their offices. The face-to-face time that comes from Gemba walks sends the message that leadership is interested in the ideas of the employees. By getting out of your office and talking to people on the front lines, you show your own dedication to rapid continuous improvement, which gives others the sense that they too can prioritize this work. Hoshin Kanri (also called Policy Deployment) is a strategic planning method that ensures everyone in an organization is driving toward the same goals. It is also a tool for balancing the need to achieve long-term goals and address daily improvement opportunities at the same time. Here are some signs to tell you if your organization would benefit from Hoshin Kanri. Unlike other approaches to planning, Hoshin Kanri is not done from the top-down. People at every level of the organization are involved in setting the priorities and laying out the plan for success. Here are some advantages of using the Hoshin Kanri approach: The practice of Kanban originated at Toyota when they applied the visualization principles that are used by grocery stores to have on hand the right level of inventory. The idea is to maximize the flow of goods and work. It is achieved through the four principles of Kanban: The technique is used by software companies, hospitals, fulfillment centers, and many other kinds of organizations. Any process where work is moved from one stage to another can benefit from the visualization that Kanban provides. The PDSA approach, sometimes called the Deming Cycle, is based on the scientific method, which approaches problems throughhypothesis (plan), experimentation (do) and evaluation (study). In business, the output of a successful PDSA cycle is a new standard that institutionalizes the improvement. The cycle can begin again and further improvement can be achieved. A PDSA cycle includes: During this phase, it is important to not jump to solution; in fact, it's often said that half of the time in a PDSA improvement cycle should be spent on this stage. The plan should identify the individuals who will be involved in testing the improvement and those who will be impacted by it, and should include a time line and a communication plan. Once you've completed the planning phase and made a hypothesis about specific changes that are expected to lead to measurable improvement, the "do" step can begin. This part of the cycle should be considered experimental - and as with a scientific experiment, careful observation and data collection is just as important as the action itself. The study step is arguably the most important of the PDSA cycle, during which the results of the experimental improvement are compared against the hypothesis, and we look to make sure that there weren't any side effects created by the change. The data gathered is analyzed to determine if a measurable improvement was achieved and if it meets the expectations defined in the planning phase. If the study phase reveals that the change was implemented as expected and resulted in the anticipated improvement (without causing any new problems), then you can begin to adjust. The improved process becomes the new baseline for future processes, standard work documents are adjusted to include the change, and performance expectations can be modified. Critically, the cycle is then repeated against the new process and additional improvements can be achieved. Standard work is the documentation of the best practices for any process or task. It must be complete, accessible, and up to date. It forms the baseline for rapid improvement activities. Establishing standard work begins with creating, clarifying, and sharing information about the most efficient method to perform a task that is currently known with everyone performing that process. Once this information has been shared, everyone practices this standard consistently so that the work is done the best way every time. This is where continuous improvement comes into play; standard work isn't a "set it and forget it" process, announced once and then permanently unchanging. Instead, everyone should work to improve the standard, and share new best practices as they're discovered. The 5 Whys is a technique for finding the root cause of a problem. The practice of the 5 Whys is deployed when a problem arises and a team wants to find and fix, not just the symptom, but theroot cause of the issue. A problem statement is created and then the team simply asks, "Why," until the root cause is revealed. The actual number of "whys" needed varies, but five seems to be about right. Unless you're my toddler, in which case you're definitely going to demand more than five. When deploying the 5 Whys, keep in mind that you are looking for flawed processes, not people. The idea is not to place blame, it is rather to uncover problems with processes, procedures or standard work. Value stream mapping is a system of visualizing the connection of every action or process required to produce a product to the value it ultimately brings to the customer. The term originated with the lean management method, but the concept can be applied to almost any value chain. The goal is to identify and reduce or eliminate processes that do not add value to the customer, and to improve those that do. The process varies from company to company and even from product to product, but generally includes the following steps: As you can see, the rapid continuous improvement toolbox is full of useful implements. Just follow grandpa's advice and be sure to pick the right tool for each job. Let us know if there are others you think should be added to this list!A3

5S

![[Watch Now] The Why, How, and What of Continuous Improvement](https://no-cache.hubspot.com/cta/default/326641/060c8cc9-44ad-4fd1-ad7b-7b4ab71c7632.png)

Catchball

DMAIC

Gemba Walks

Hoshin Kanri

Kanban

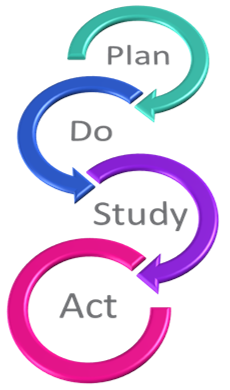

PDSA

Standard Work

The 5 Whys

Value Stream Mapping (VSM)

Although it is a relatively simple idea, value stream mapping is an extremely useful way to help organizations focus on structuring processes around customer needs. It can identify opportunities for improvement and help eliminate processes that are not contributing to customer satisfaction.

Topics: Spread Continuous Improvement

Process Improvement Tools Design Intern Michigan

Source: https://blog.kainexus.com/continuous-improvement/11-rapid-continuous-improvement-tools-and-techniques-explained

Posted by: southwoodperaweltake.blogspot.com

0 Response to "Process Improvement Tools Design Intern Michigan"

Post a Comment